Microfilter & filter element

Microfilter

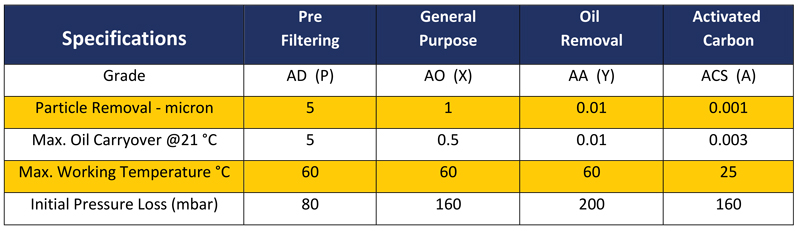

Due to the corrosiveness of dust, polluting particles and oil in the compressed air coming out of the compressors, they cause serious damage to the machines, faucets and compressed air pipes. The microfilter has the main role in separating oil, dust particles, and oil vapors from the compressed air.

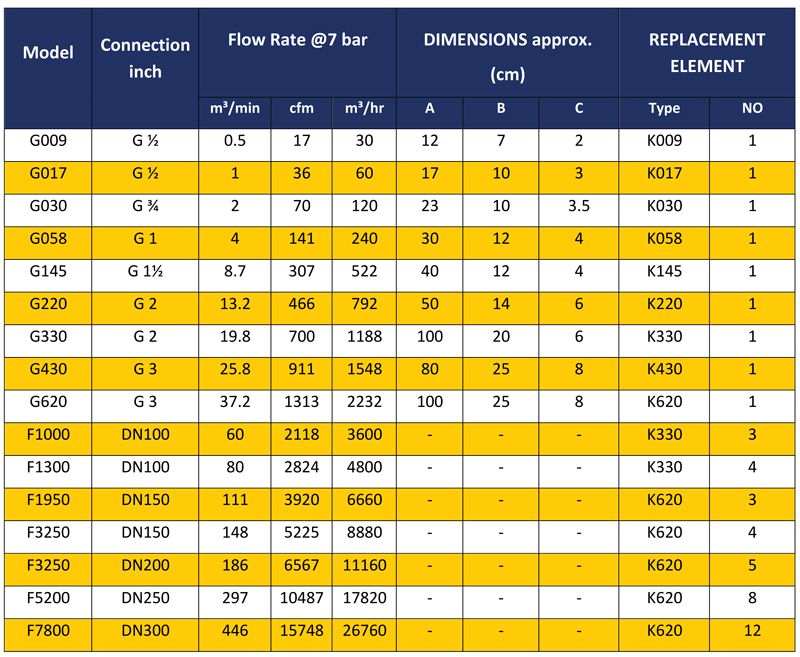

Microfilters with the ability to absorb particles from 5 micron to 0.003 micron are used in the compressed air line to get air free of any dust and oil vapors.

Microfilter

- Shell or housing: according to the model selected by customers, the material of the shell is aluminum alloy, cast aluminum alloy, or carbon steel and the filter elements are placed inside these shells.

- Filter Element: It is the main part and absorber of pollutant particles in compressed air filtration. Usually, these filters should be replaced after 2 to 3 thousand hours of operation or six months after the first use.

- Manual or electric auto drain valve: Each microfilter has a drain valve, which can be installed on the timer electric drain valve, mechanical drain valve, or manual valve upon customer request.

- ∆P or deltapi indicator for replacement of element filter: it works based on the difference between the input and output pressure of the microfilter and shows the time to replace the element filter to the operator - (optional)

- Base (only in F1000 to F7800 models)